Electric vehicle batteries are typically made of anode, cathode, separator, electrolyte, and lithium ions. They are composed of rechargeable lithium-ion cells connected together to form the battery pack.

Electric vehicle batteries are an essential component of electric cars, providing the power needed for propulsion. These batteries are made up of various materials, including graphite for the anode, metal oxides such as cobalt, nickel, and manganese for the cathode, a separator that prevents the electrodes from touching and causing a short circuit, an electrolyte that allows the flow of ions between the electrodes, and the lithium ions themselves that move back and forth between the anode and cathode during charging and discharging.

The production of electric vehicle batteries involves a complex supply chain and the extraction of raw materials such as lithium, cobalt, nickel, and manganese. However, the environmental impact and recycling of these batteries are also important considerations.

Introduction To Electric Vehicle Batteries

Electric vehicle batteries are typically made up of anodes, cathodes, separators, electrolytes, and lithium ions. These rechargeable lithium-ion cells are connected to form the battery pack, allowing electric cars to operate efficiently. The raw materials used in EV batteries, such as aluminium, copper, and iron, play a vital role in their manufacturing process.

Brief Overview Of The Importance Of Electric Vehicle Batteries

Electric vehicle batteries are an integral component of electric vehicles (EVs), playing a crucial role in their performance and functionality. These batteries power the vehicle, allowing it to run on electricity and eliminating the need for gasoline or diesel fuel.

EV batteries provide a range of advantages, including lower greenhouse gas emissions, reduced dependence on fossil fuels, and quieter operation compared to traditional combustion engines. They are also a key factor in driving the transition to more sustainable transportation options.

As the demand for EVs continues to grow, understanding electric vehicle batteries and their composition becomes increasingly important. So, let’s explore the question: “What are Electric Vehicle Batteries Made of?”

Components Of Electric Vehicle Batteries

When it comes to electric vehicle batteries, understanding their components is crucial. These batteries are made up of various elements that work together to power the vehicle. In this section, we will provide an overview of the different components used in electric vehicle batteries, including the anode, cathode, separator, electrolyte, and lithium ions.

Anode

The anode is one of the key components of an electric vehicle battery. It is responsible for storing and releasing electrons during the charging and discharging process. Typically, the anode is made of graphite, which has excellent electrical conductivity and stability.

Cathode

The cathode is another essential component of the electric vehicle battery. It acts as the positive electrode and plays a crucial role in the movement of lithium ions during charging and discharging. The composition of the cathode can vary, but commonly used materials include cobalt, nickel, and manganese.

Separator

Between the anode and cathode lies the separator, which prevents short circuits by keeping the two electrodes separate. The separator allows the flow of lithium ions while preventing the direct contact between the anode and cathode. It is usually made of a porous material, such as polyethylene.

Electrolyte

The electrolyte serves as a medium for the flow of charged particles between the anode and cathode. It enables the movement of lithium ions during the battery’s operation. Typically, the electrolyte in electric vehicle batteries is made of a lithium salt dissolved in an organic solvent.

Lithium Ions

Lithium ions are the carriers of electric charge in electric vehicle batteries. They flow from the anode to the cathode during discharging and from the cathode to the anode during charging. The movement of lithium ions is essential for the battery’s function and determines its overall performance.

In conclusion, electric vehicle batteries are complex systems consisting of different components, including the anode, cathode, separator, electrolyte, and lithium ions. Each component has a specific role in the battery’s operation, ensuring efficient and reliable power for electric vehicles.

Anode: The Positive Electrode

Anode: The Positive Electrode is a crucial component of electric vehicle batteries. It is typically made of graphite and is responsible for storing and releasing lithium ions during the charging and discharging process.

Explain The Role Of The Anode In Electric Vehicle Batteries

The anode is an integral component of electric vehicle batteries, serving as the positive electrode. It plays a crucial role in the battery’s overall functionality and performance.

Describe The Materials Typically Used For The Anode, Such As Graphite Or Lithium

Commonly, electric vehicle batteries utilize materials such as graphite or lithium for the anode, which contribute to the efficient operation of the battery.

Graphite is a widely used material for the anode due to its exceptional conductivity and stability. It can efficiently store and release lithium ions during charging and discharging processes. The layered structure of graphite allows for easy intercalation of lithium ions, making it well-suited for use in electric vehicle batteries.

Lithium, on the other hand, can also be utilized as an anode material. However, it requires pairing with another material such as silicon to enhance its performance. Lithium offers advantages such as high energy density, promoting longer battery life and improved overall battery performance.

It is worth noting that the choice of anode material can impact the battery’s specific energy, power density, and overall efficiency. Manufacturers carefully consider these factors in order to optimize the performance of electric vehicle batteries.

Cathode: The Negative Electrode

The cathode is a crucial component of electric vehicle (EV) batteries and serves as the negative electrode in the battery system. It plays an essential role in the overall performance and efficiency of the battery.

Explain The Role Of The Cathode In Electric Vehicle Batteries

The cathode is responsible for the movement and storage of positive ions (lithium ions) during the charging and discharging process. When the battery is connected to a power source, the cathode attracts and stores the lithium ions, creating an electric current flow. This stored energy is then released when the battery is being used to power the vehicle. Therefore, the cathode is crucial in allowing the battery to store and deliver energy efficiently.

Discuss The Materials Commonly Used For The Cathode

There are several materials commonly used for the cathode in EV batteries. These materials include cobalt, nickel, and manganese, among others. Each material has its own unique characteristics and impact on the battery’s performance.

- Cobalt: Cobalt is a popular choice for cathode materials due to its high energy density, which allows for longer driving ranges. However, cobalt is a relatively expensive material, and its extraction and refining processes can have environmental and social impacts.

- Nickel: Nickel is another commonly used cathode material. It offers a good balance between energy density and cost and can improve the overall performance of the battery. However, high nickel content can lead to decreased stability and safety concerns.

- Manganese: Manganese is often combined with other materials, such as nickel, to create cathodes with improved stability and safety. Manganese-based cathodes are more affordable compared to cobalt and nickel-based ones. However, they generally have lower energy density.

The selection of cathode materials in EV batteries involves a trade-off between energy density, cost, safety, and sustainability. Ongoing research and development efforts aim to improve the performance of cathodes and explore alternative materials that can provide higher energy density, lower cost, and reduced environmental impact.

Separator And Electrolyte: Ensuring Safety And Conductivity

Electric vehicle batteries are made of various components, including anode, cathode, separator, electrolyte, and lithium ions. These materials ensure both safety and conductivity in the batteries, allowing for efficient and reliable operation in electric vehicles.

When it comes to electric vehicle batteries, there are two crucial components that play a vital role in ensuring both safety and conductivity – the separator and the electrolyte. Let’s dive deeper into the importance of these essential elements.

Discuss The Importance Of The Separator And Electrolyte In Electric Vehicle Batteries

The separator and electrolyte are key components in electric vehicle batteries. They work hand in hand to ensure the safe and efficient operation of the battery. Let’s explore their significance individually.

Explain The Function Of The Separator In Preventing Short Circuits

The separator acts as a physical barrier between the anode and cathode of the battery, preventing direct contact and potential short circuits. It is typically made of a thin, porous material that allows the passage of lithium ions while maintaining a barrier between the electrodes. This prevents any internal short circuits that could lead to battery failure or even thermal runaway. By ensuring the integrity of the separator, the risk of electrical malfunction is significantly reduced, ensuring the safety of both the vehicle and its occupants.

Describe The Role Of The Electrolyte In Facilitating The Movement Of Lithium Ions

The electrolyte is a conductive medium that allows the movement of lithium ions between the anode and cathode of the battery. It is usually made up of a solution or gel containing lithium salts, such as lithium hexafluorophosphate or lithium bis(trifluoromethanesulfonyl)imide.

The electrolyte plays a crucial role in facilitating the movement of lithium ions during charging and discharging cycles. When the battery is being charged, lithium ions are extracted from the cathode and move through the electrolyte to the anode, where they are stored. On the other hand, during discharge, the lithium ions move from the anode back to the cathode, releasing stored energy.

By allowing the smooth flow of lithium ions, the electrolyte ensures the battery’s efficient operation and performance. It helps maintain the stability of the electrical current, contributing to the longevity and reliability of the battery. Additionally, the electrolyte also aids in managing the temperature within the battery, as certain formulations have inherent properties that serve as a thermal regulator.

Lithium Ions: The Energy Carriers

Electric vehicle batteries, including those used in Tesla cars, are typically made of rechargeable lithium-ion cells connected together to form the battery pack. These cells consist of components such as anode, cathode, separator, electrolyte, and lithium ions. The raw materials for lithium batteries come from various sources, and their manufacturing can have social and environmental impacts.

Explore The Significance Of Lithium Ions In Electric Vehicle Batteries

When it comes to electric vehicle batteries, one key element that plays a crucial role in their functionality is lithium ions. These tiny charged particles, also known as lithium ions, act as the energy carriers in the batteries, allowing for the storage and release of energy.

Explain How Lithium Ions Are Responsible For Storing And Releasing Energy

In electric vehicle batteries, lithium ions move back and forth between the anode and cathode, storing and releasing energy in the process. Let’s take a closer look at how this happens:

- Lithium ions are initially stored in the anode, typically made of graphite. As the battery charges, lithium ions are attracted to and stored within the anode structure.

- During the discharge process, lithium ions migrate from the anode through the electrolyte, towards the cathode.

- The cathode, made of varying combinations of cobalt, nickel, and manganese, acts as the positive electrode. It receives the incoming lithium ions and stores them, allowing the battery to hold its charge.

- When the electric vehicle is in use, the stored lithium ions are released from the cathode and move back to the anode, creating an electrical current that powers the vehicle.

This continuous movement of lithium ions between the anode and cathode is what enables electric vehicle batteries to store and release energy, providing the necessary power to drive these eco-friendly vehicles.

The Ev Battery Supply Chain

The EV battery supply chain plays a crucial role in the development and production of electric vehicle batteries. It encompasses various actors and processes involved in transforming raw materials into the advanced lithium-ion batteries used in electric vehicles. This section will provide an overview of the EV battery supply chain, discuss the global dominance of China in this industry, and highlight the key players involved in the battery manufacturing process.

Provide An Overview Of The Ev Battery Supply Chain

The EV battery supply chain consists of multiple stages that work cohesively to produce high-quality batteries for electric vehicles. These stages include:

- Raw Material Extraction: At this stage, raw materials such as lithium, cobalt, nickel, manganese, graphite, aluminum, copper, and iron are extracted from mines or obtained through recycling processes.

- Raw Material Processing: The extracted raw materials then undergo a series of processing steps such as refining, purification, and chemical treatments to meet the required specifications for battery production.

- Battery Component Manufacturing: In this phase, the processed raw materials are transformed into battery components such as anodes, cathodes, separators, and electrolytes.

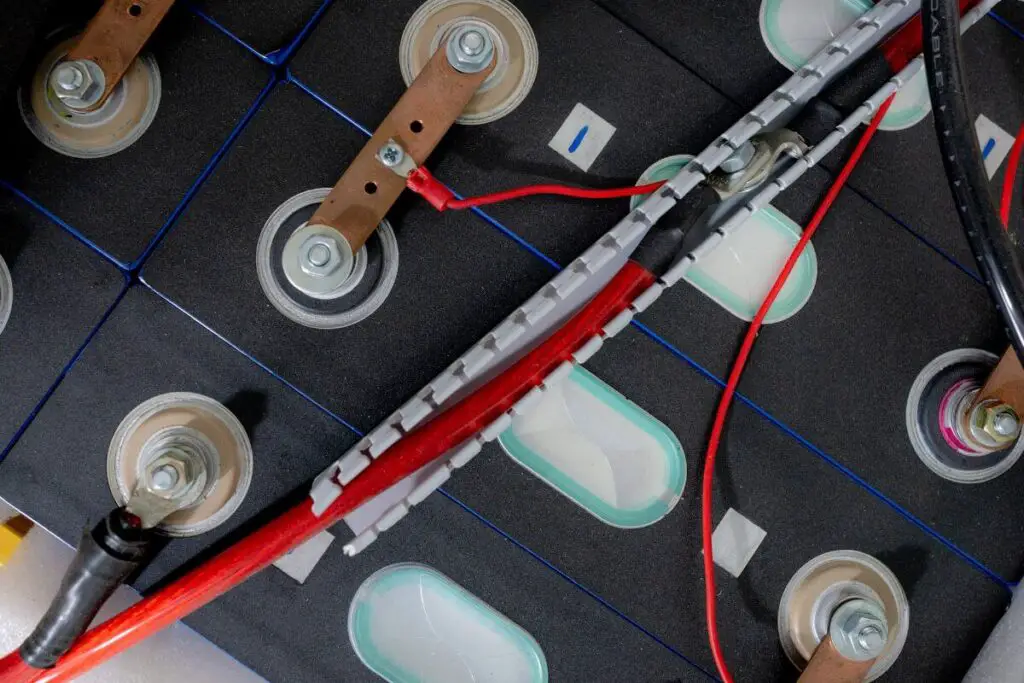

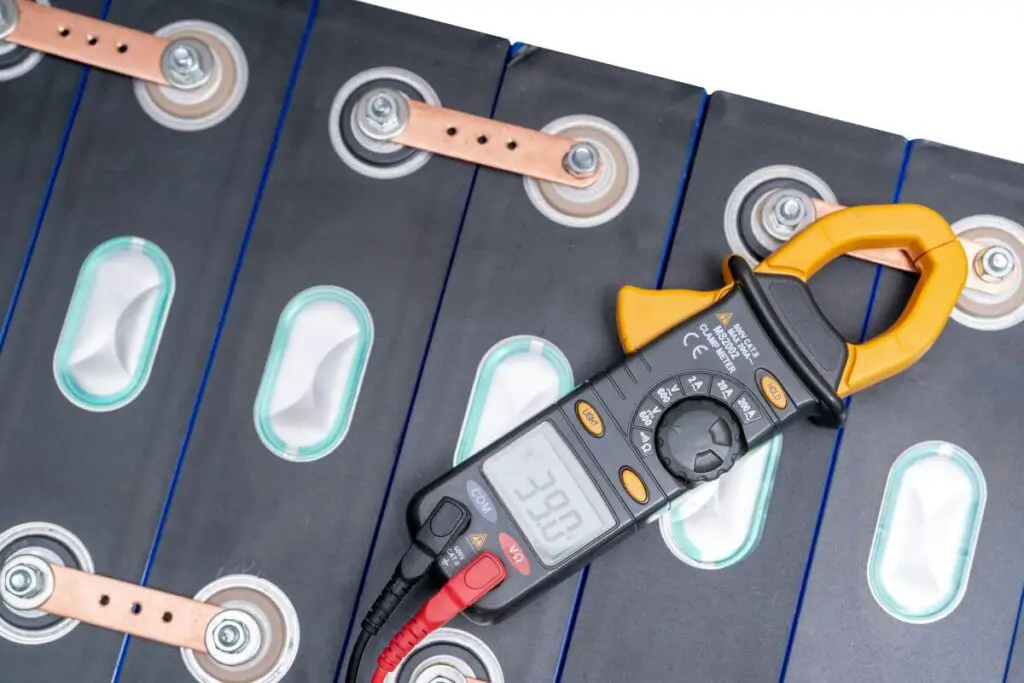

- Battery Cell Assembly: The battery components are then assembled into individual battery cells, which are the building blocks of the final battery pack. This involves precise techniques and quality control measures to ensure the optimal performance and safety of the cells.

- Battery Pack Integration: The battery cells are connected together to form the battery pack, which is customized to fit the specific requirements of different electric vehicle models. This integration process includes the addition of advanced thermal management systems and safety features.

- Distribution and Installation: Once the battery packs are manufactured, they are distributed to electric vehicle manufacturers for installation in their vehicles. This stage involves logistics, transportation, and strategic partnerships between battery manufacturers and automakers.

Discuss The Global Dominance Of China In The Supply Chain

When it comes to the EV battery supply chain, China currently holds a dominant position globally. Chinese companies lead the production of both battery components and battery cells, making China a key player in the global electric vehicle market. The country benefits from abundant access to critical raw materials for battery production, such as lithium and cobalt.

Moreover, China’s manufacturing capabilities, advanced technologies, and competitive cost structures have further fueled its dominance. Chinese battery manufacturers have been able to scale up production rapidly and offer cost-effective solutions, attracting global electric vehicle manufacturers to source their batteries from China.

Mention The Various Actors Involved In Transforming Raw Materials Into Batteries

The transformation of raw materials into batteries involves the collaboration of several actors in the supply chain:

- Raw Material Suppliers: These companies extract and supply the essential raw materials needed for battery production, such as lithium, cobalt, nickel, and graphite.

- Battery Component Manufacturers: Companies specializing in this area produce battery components like anodes, cathodes, separators, and electrolytes, ensuring they meet the required standards for performance and safety.

- Battery Cell Manufacturers: These manufacturers assemble the battery components into individual cells, often incorporating advanced technologies and specific chemistries to enhance performance and energy density.

- Battery Pack Integrators: These companies integrate the battery cells into complete battery packs, customized to match the specifications and requirements of different electric vehicles.

- Electric Vehicle Manufacturers: These companies incorporate the battery packs into their vehicles, utilizing them as the primary power source for electric propulsion.

This collaborative effort among various actors ensures the smooth flow of materials, efficient manufacturing processes, and the delivery of high-quality electric vehicle batteries to the market.

Environmental Impact Of Electric Vehicle Batteries

Electric vehicle batteries are typically made up of rechargeable lithium-ion cells connected together to form the battery pack. These cells consist of an anode, cathode, separator, electrolyte, and lithium ions. The materials used vary, but commonly include graphite, cobalt, nickel, manganese, aluminum, copper, and iron.

Discuss The Potential Environmental Impact Of Electric Vehicle Battery Production

When it comes to electric vehicle battery production, there are potential environmental impacts that need to be considered. From the extraction of raw materials to the manufacturing process, each stage of production can have consequences for the environment. In this section, we will focus on the key issues associated with the production of electric vehicle batteries and their potential environmental impact.

Mention The Issues Associated With Lithium Mining

Lithium, a key component of electric vehicle batteries, is mainly obtained through mining. However, the process of extracting lithium from the earth can have several negative environmental impacts. Let’s take a closer look at these issues:

Water and Energy Consumption

The process of mining lithium consumes significant amounts of water and energy. Water is required for various stages of the mining process, including brine extraction, water purification, and waste disposal. This can strain local water sources and put pressure on already scarce water supplies.

Moreover, high-energy inputs are needed for lithium extraction, including pumping, heating, and processing. This energy consumption contributes to greenhouse gas emissions and increases the carbon footprint associated with lithium production.

Pollution

Lithium mining can also result in pollution of air and water. The extraction process involves the use of chemicals and heavy metals that can leach into the surrounding environment, contaminating local ecosystems. This pollution poses risks to both human health and wildlife.

Habitat Disruption and Soil Erosion

Mining lithium can disrupt wildlife habitats, as it often involves clearing large areas of land for extraction sites. This clearance can lead to the displacement or loss of plant and animal species, causing ecological imbalances. Additionally, the removal of vegetation can lead to soil erosion, further degrading the local environment.

Overall, the extraction of lithium for electric vehicle batteries can have serious environmental impacts, including water and energy consumption, pollution, habitat disruption, and soil erosion. These factors highlight the importance of developing sustainable methods for raw material extraction and battery production in the electric vehicle industry.

Conclusion

Electric vehicle batteries are typically made up of rechargeable lithium-ion cells connected together to form the battery pack. These cells consist of various materials such as graphite for the anode and combinations of cobalt, nickel, and manganese for the cathode.

Other important components include the separator and electrolyte. The battery supply chain involves several actors who transform raw materials into the sophisticated devices we use. Although mining lithium for these batteries has environmental concerns, advancements in battery technology and recycling contribute to a more sustainable future for electric vehicles.

Frequently Asked Questions

Is Mining Lithium Bad For The Environment?

Mining lithium can have negative impacts on the environment. It consumes a lot of water and energy, leading to pollution of air and water with harmful chemicals and heavy metals. It also disrupts wildlife habitats and causes soil erosion, resulting in long-term ecological damage.

What Is The Main Material For Ev Battery?

Electric vehicle batteries are primarily made of thousands of rechargeable lithium-ion cells connected together to form the battery pack. These cells contain anode, cathode, separator, electrolyte, and lithium ions. The main cathode types used in Tesla EVs are nickel-cobalt-aluminum (NCA).

What Are Tesla Car Batteries Made Of?

Tesla car batteries are primarily composed of lithium-ion cells, which make up the battery pack. These cells consist of anodes, cathodes, separators, and electrolytes. The specific cell chemistry used by Tesla includes nickel-cobalt-aluminum (NCA) cathodes.

Where Do The Raw Materials For Lithium Batteries Come From?

Raw materials for lithium batteries are sourced from various locations around the world. Lithium, cobalt, nickel, manganese, graphite, aluminum, copper, and iron are important ingredients in the production of electric vehicle batteries. The mining process for these materials can have negative environmental impacts such as water and energy consumption, pollution, and habitat disruption.

However, efforts are being made to ensure responsible sourcing and recycling of battery materials to mitigate these issues.